Home > Thermoformers > EP9000 M

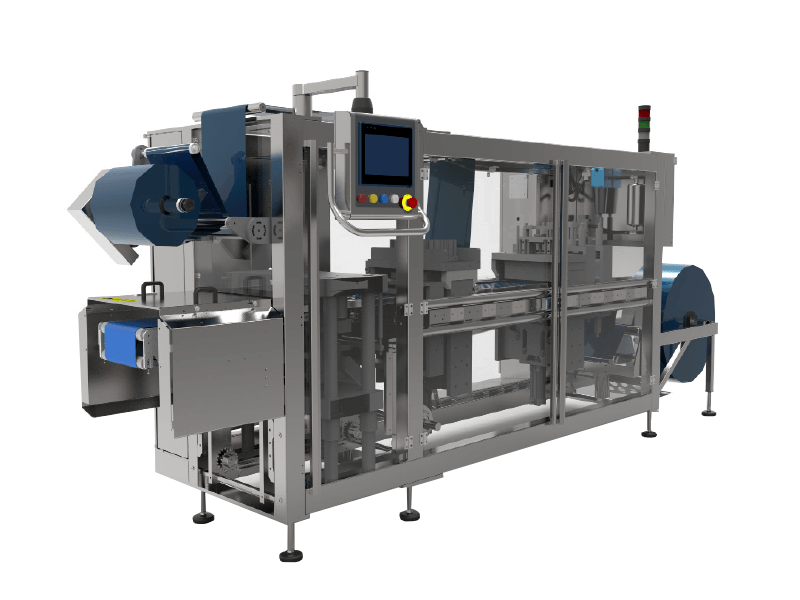

EP9000 M

Shape cutting process

with precutting integrated process

to prepare the pack on the same station

with precutting integrated process

to prepare the pack on the same station

Hygienic design

for high cleanable process

for high cleanable process

DIP POT HFFS packaging line

Compact configuration Sealing process,

up to 20cpm and 250ppm

Compact configuration Sealing process,

up to 20cpm and 250ppm

Full covered process

For laminar flow and dosing

process integration

For laminar flow and dosing

process integration

At a glance

- Designed for DIP pot packaging solutions.

- Ideal for rigid pack and top lid applications.

- Supports sealing process, ensuring optimal product preservation.

Key features

General Configuration

- Configurable thermoformer

- Machine Length: 16' frame

- Rigid pack for top lid process

Film Specifications

- Film Thickness : Up to 40 mil

- Film Width : Machine frame up to 13,4"

- Advance Step: Up to 8,5"

Forming & Sealing Process

- Forming : Independant station / Separated preheating and froming station / forming station with forming mechanical assistance / without cooling process

- Sealing : Independant station without cooling process

Cutting Mechanism

- Transversal : Shape cutting station

Introducing the EP9000 M

Designed for DIP pot packaging with high efficiency.

Capable of reaching speeds of up to 25 cycles per minute, this HFFS machine is equipped with key options like jumbo top and bottom film roll alimentation, laminar air flow, dosing process, and a material dust cleaning device.

Watch the video to explore how the EP9000 can optimize your production

Comparison table

Machine and die

Machine on stock

Machine device on stock / Machine configuration on order

Machine customization on order

Quick Change Over (10 min)

Specific Design

Vacuum

Sealing

MAP

Skin

*Also exist for Medical purpose.